2012

The Advent of Diving System Assurance - Audits / Failure Mode Effect Analysis

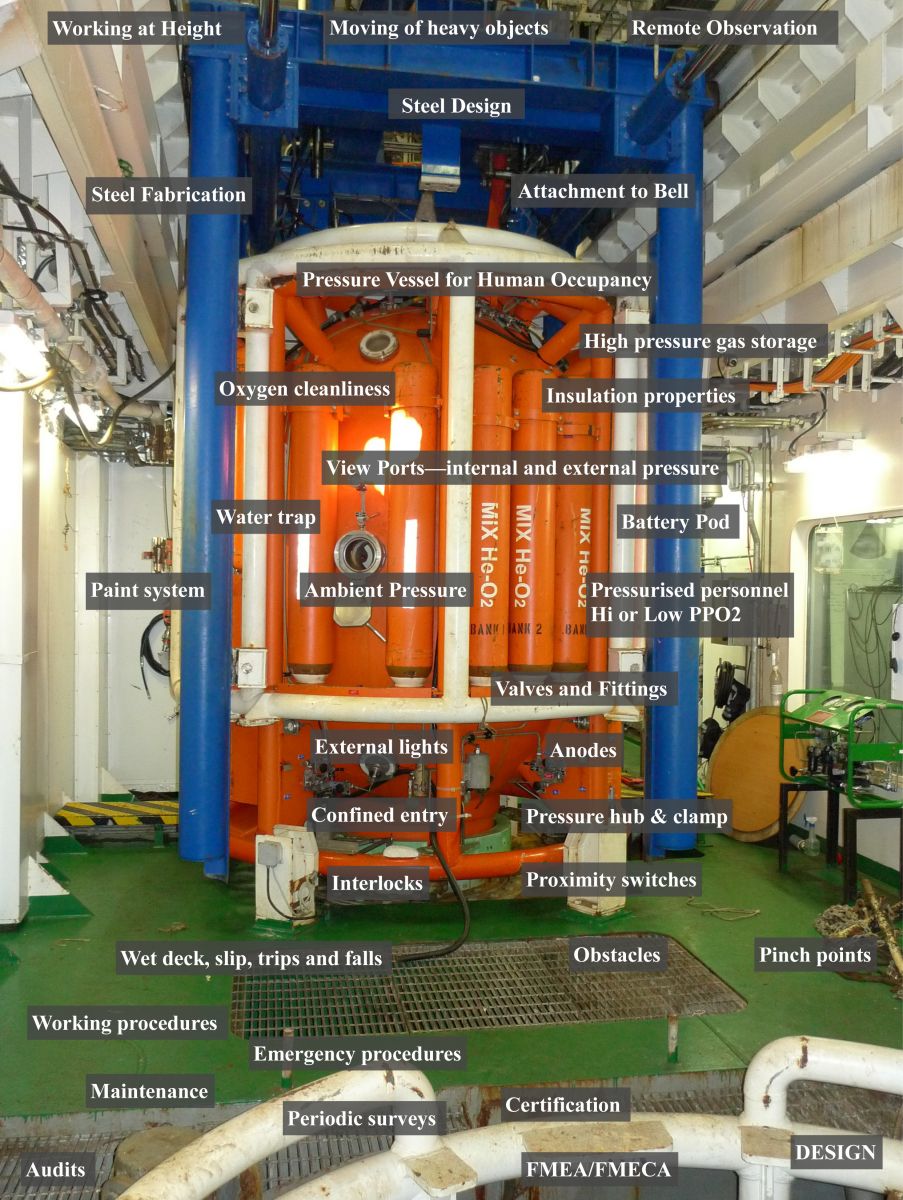

In recent times, the process of Failure Mode Effect Analysis (FMEA) / Failure Mode Effect Critical Analysis (FMECA) has become more of a requirement when looking at diving system assurance. Where in the past, documents such as DESIGN audits or FMEA/FMECA were produced and accepted on face value, increasingly these days the content is more closely scrutinised.

International Marine Contractors Association (IMCA) produces a great deal of industry guidance and best practice documents, while national governing authorities and class societies provide rules and / or regulations. Even following these alone is not the complete assurance process! The process often includes individual behavioral aspects or engineering requirements as well as trade standards such as British Standards International (BSI), International Organisation for Standardisation (ISO) or American Society of Mechanical Engineers (ASME).

KB Associates Pte Ltd (KBA) has, over the past 10 years of operation, conducted over 700 such audits and has taken a lead in conducting the FMEA /FMECA process by developing their own software that assists the FMEA team members in identifying the system and components that are required to be assessed. Then using the input data from the team members the Failure Modes and Criticality of the system / component is formulated and resultant data sheets are produced. This data is then used to ‘test’ the system/component to ensure the failure results are as expected; these are then documented. The ‘test’ is the all-important function that is missing from many FMEA/FMECA documents in today’s industry. Significant effort to gain reader acceptance, understanding and ‘buy in’ has been put into the design of the document, with a clear message that this document is for growth in a live environment and needing the input of those working the system.

To complement this development in assurance awareness, KBA Training Center offers a diving system assurance course as a one, three or five day intensive and interactive training experience which requires the participation of the students who at first have their eyes opened to the width of the task, take on a mini audit, discuss the process and finally randomly review safety alerts. From the newly appreciated understanding, they seek to consider the If/Could question. That is “If an already in place document were used prior to the event, ‘Could’ an introduced process have prevented the occurrence”.

It might seem nothing new however, it is clear that the process has not been previously understood by all. Documents holistically termed ‘Assurance’ (including DESIGN audits, FMEA/FMECA, generic risk assessments etc.) are stacked neatly on shelves and not touched until the next audit requirement be it annually or by client request. Oil and Gas clients have realised this and have embraced a training approach, but they are not the only ones; contractors have embraced this process as it builds in awareness to their personnel, contributing to a safer and more efficient work environment. Even individuals are seeking attendance on such courses, indicating that they too are seeing this recognised awareness as a necessary string to their competence development.

With over 100 people having attended the training providing positive course ‘feedback’, KBA’s target is to get all personnel to achieve this level of understanding, keeping the process alive and functioning. Tim Fraser, Diving Superintendent of Technip UK commented “The course is well presented and very informative. It has met my expectation and improved my knowledge in my profession. The trainer understands his subject, able to communicate and transfer his know-how really well. Throughout my career (36 years) in Diving, there are only a few training courses that have stayed in my mind and this ‘Diving System Assurance Training’ is one of which is very relevant”.

Check out the article that was published in Underwater Contractor Internation (UCI) Magazine - Sept/Oct 2012 Issue